Understanding Clamp-on Pallet Forks: A Versatile Material Handling Solution

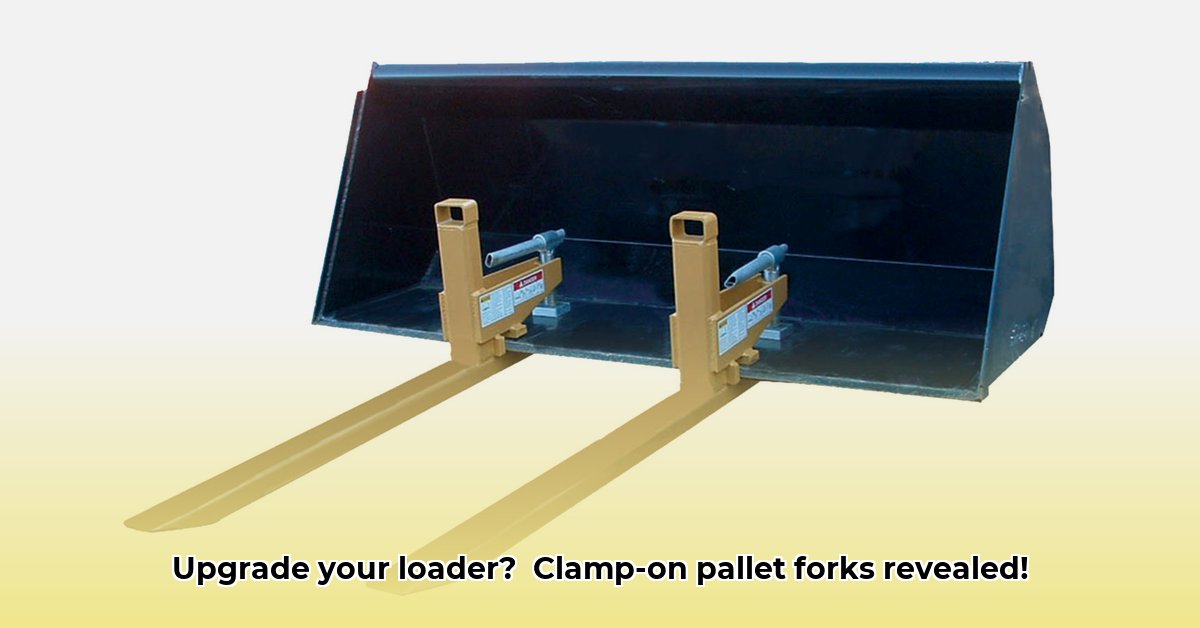

Clamp-on pallet forks are attachments that transform loader tractors into efficient material-handling machines. Unlike permanently mounted forks, these are easily attached and removed, offering flexibility for various tasks. This guide will explore their types, selection, safe operation, and overall cost effectiveness, equipping you with the knowledge to make an informed decision. But first, let's examine why these versatile tools are a valuable asset. For more information on quick-attach options, check out this helpful resource: tractor pallet forks.

Wouldn't it be great to streamline your material handling process, saving time and resources? Clamp-on pallet forks offer a practical solution for moving palletized goods efficiently. Their adaptability makes them ideal for diverse applications, from farming to construction.

Types of Clamp-on Pallet Forks: Capacity, Material, and Mechanisms

Choosing the right pallet forks depends on several key factors. Here's a breakdown to help you navigate the options:

Lifting Capacity: Matching the Load

Forks are rated by their lifting capacity, ranging from handling lighter loads to heavier-duty applications capable of lifting several tons. It's crucial to select forks with a capacity exceeding your heaviest anticipated load, always keeping a safety margin. Overloading is dangerous.

Construction Material: Durability and Longevity

Standard steel is common, but stronger alloys, such as high-strength steel, offer superior durability and a longer lifespan, especially for frequent heavy use. The material choice directly impacts the fork's resistance to wear and tear.

Clamping Mechanisms: Hydraulic vs. Mechanical

Two main clamping mechanisms exist: hydraulic and mechanical. Hydraulic systems offer smoother and more controlled clamping, while mechanical systems tend to be simpler and potentially less expensive. Consider your budget and the level of precision needed.

Fork Length: Ensuring a Proper Fit

While standard lengths are widely available, custom lengths might be necessary to accommodate specific pallet dimensions. Accurate measurement is crucial to ensure stability and prevent damage to the pallets.

Choosing the Right Forks: A Step-by-Step Selection Process

Selecting the best pallet forks requires a systematic approach. Follow these steps to optimize your choice:

Assess Your Needs: Define your typical loading requirements: pallet size, weight, frequency of use, and types of materials handled. This assessment forms the basis for your selection criteria.

Verify Tractor Compatibility: Check your tractor's specifications—particularly its lift capacity and mounting system—to ensure the selected forks are compatible and safe to operate. Never exceed the tractor's rated lift capacity.

Prioritize Safety Features: Look for robust clamping systems, safety locks, and other features designed to prevent accidental load drops. Safety should always be your top priority.

Consider Long-Term Costs: While the initial cost is important, assess the long-term value. Higher-quality forks, while more expensive upfront, often provide superior durability and a longer life cycle, reducing maintenance costs over time.

Safe Operation and Maintenance: Preventing Accidents and Ensuring Longevity

Safe operation is paramount. Regular maintenance is key to preventing accidents and ensuring that your investment serves you for many years to come.

Pre-Use Inspection: Before each use, meticulously inspect the forks for any damage, loose components, or hydraulic fluid leaks (for hydraulic systems). Addressing issues promptly prevents potential hazards.

Correct Attachment: Always follow the manufacturer's instructions when attaching the forks to your loader. Incorrect attachment can lead to instability and accidents.

Safe Load Handling: Never overload the forks beyond their rated capacity; always center the load for stability. Use slow, controlled movements to prevent damage or injury.

Regular Maintenance: Lubricate moving parts as prescribed by the manufacturer. Replace worn-out or damaged components promptly to prevent failures.

Adherence to Safety Standards: Familiarize yourself with and adhere to relevant safety regulations and best practices. Remember, a few minutes of preventative safety checks can avert serious accidents.

Cost Considerations: Balancing Upfront and Long-Term Expenses

The initial cost of clamp-on pallet forks varies based on features and capacity. However, remember to look beyond the initial price tag.

- Initial Purchase Price: Higher-quality materials typically translate into lower replacement costs over time.

- Maintenance and Repair: Regular maintenance significantly reduces the likelihood of expensive repairs.

- Increased Efficiency: Faster material handling saves time and labor.

- Reduced Labor Costs: Using pallet forks requires less manual handling, saving labor costs.

- Extended Lifespan: Proper maintenance maximizes the lifespan of your investment.

Conclusion: Enhancing Efficiency and Safety Through Informed Choice

Clamp-on pallet forks offer a powerful solution for efficient material handling, but safe and effective use depends on careful selection, proper maintenance, and adherence to safety protocols. By understanding the various types, assessing your needs, and prioritizing safety, you can unlock the significant time and cost savings these tools offer. Remember: safety is not just a cost; it’s an investment.